Input Power:

105 to 135 VAC, 50/60 Hz, 30 W Operating

Temperature:

-10°F to 122°F (-23°C to 50°C)

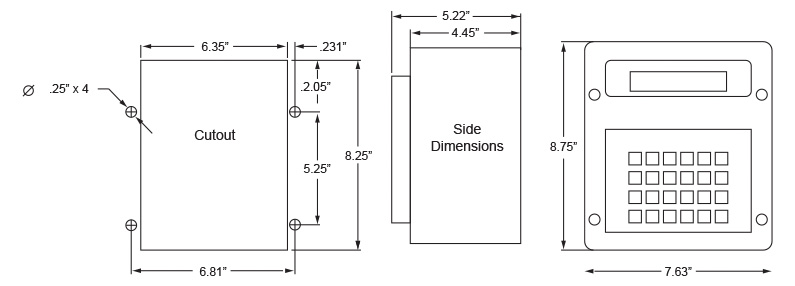

Dimensions:

7.6” W x 8.7” H x 5-1/4” D

RESOLVER INTERFACE

Position Transducer:

Resolver, Autotech’s Series E7R and RL100

Cable Length between Resolver and M1200:

2500 feet max, toil shielded,

Resolver Cable:

Autotech’s CBL-10T22-Mxxx

PROGRAMMING

Scale Factor:

Fixed at 360

Offset:

Programmable from 0 to 359; common to all

Die Protection and PLS programs

Die/Tool Identification:

One 8-character name per program.

Search by name.

Number of Programs or Setups:

60 programs

DIE PROTECT SPECIFICATIONS

Number of Sensors:

4, Expandable to 12

Event Detection:

Programmable rising edge, falling edge,

pulse, pos hi or pos low detection within

programmed window.

Die Protection Fault Output:

Programmable for each sensor:

E-STOP: Stops the press immediately (See

Engagement Angle).

T-STOP:

Stops the press at top.

Sensors can selectively be disabled.

Sensor Name:

One 8-character name per sensor. Ability to

select names from a library or enter a

customized name.

Slug Detect Delay:

Programmable number of stroke delays

between the detection of a slug fault and

the deactivation of the E-Stop or T-Stop

output.

E-Stop Engagement Angle:

Programmable angle from 90° to 190°.

E-Stop does not occur between Engagement

Angle and 190°.

Top-Stop Angle:

Programmable angle at which the Top Stop

output is activated, when required.

COUNTERS

Batch Counter:

Six digit presettable down counter. Counts

down to zero. Top Stop output de-energizes

at programmable T-Stop Angle, Resettable

from keypad or input.

Quality Counter:

Six digit presettable down counter. Counter

output de-energizes at programmable

T-Stop Angle when Quality Counter = 0

|

|

Total Counter:

Six digit resettable up counter. Resets at

power up or from keypad or input.

Tool Counter:

Six digit tool specific up counter. Resets

from keypad.

INPUTS

Electrical Specifications (all inputs)

Optical isolation:

1500 V

Logic Levels (except 120V Brake Input):

TRUE: <1.0 VDC @ 7ma (or terminal

tied to Sig Ref. (J9-1)

FALSE: 20 to 24 VDC (or open circuit)

Fault Reset:

TRUE: Resets all faults including Die

Protection, Brake Wear, and Motion

Program and Supervisor Enable:

TRUE: Allows programming of parameters.

FALSE: Parameters can only be viewed.

Output Enable:

TRUE: allows all outputs to function

FALSE: De-energizes all outputs

Batch, Quality, and Total Reset:

Three separate inputs, one for each

TRUE: Resets the desired counter to

its preset value

FALSE: No action

OUTPUTS

Fault Output:

Detects resolver broken wire and M1200

internal faults. Without Fault: Relay

remains energized.

With Fault:

Relay de-energized.

Motion Output:

Relay energized when resolver RPM is

between programmed high and low motion

limits.

E-STOP Output:

Relay de-energized when Die Protection

Fault is detected. When no fault detected,

relay stays energized.

T-STOP Output:

Relay de-energized when Die Protection

Fault is detected. When no fault detected,

relay stays energized.

Counter Out:

Relay de-energized when Quality Counter

equals zero. Relay energized when counter

is non-zero.

TYPES OF OUTPUTS

A. Electromechanical SPST Relay:

10 Amp resistive continuous @120VAC

PLS SPECIFICATIONS

Number of PLS Outputs:

4, Expandable to 14

PLS Setpoints:

17 per program

Speed Compensation:

(Available for Channels 1-6 only):

Programmable up to 359 degrees per 100

rpm. Each PLS channel has its own speed

compensation.

|